The Future of Orthodontic Treatments

A 3D Perspective

In the ever-evolving landscape of orthodontics, advancements in technology have paved the way for more convenient, comfortable, and effective treatments. Among these innovations, orthodontic treatments with aligners have emerged as a frontrunner, offering patients a discreet and customizable solution to achieve their desired smiles. At the forefront of this revolution is Invisalign, leveraging state-of-the-art 3D printing technology to redefine the orthodontic experience.

Traditionally, orthodontic treatments often involved cumbersome metal braces, which not only affected the aesthetics but also posed challenges in terms of comfort and maintenance. However, with the advent of aligner-based treatments like Invisalign, patients now have access to a more patient-friendly alternative.

One of the key factors driving the popularity of Invisalign aligners is the utilisation of cutting-edge 3D printing technology in their production process. Unlike traditional manufacturing methods, which rely on moulds and manual adjustments, Invisalign harnesses the power of 3D Systems’ Stereolithography (SLA) 3D printers to create bespoke aligners tailored to each patient’s unique dental structure.

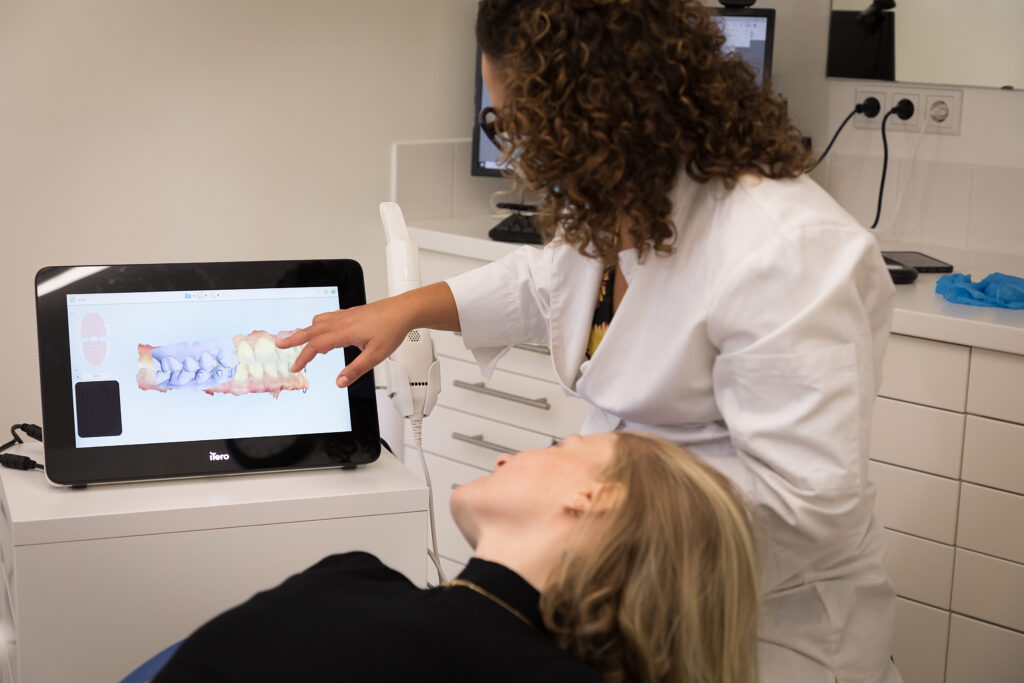

The process begins with a digital scan of the patient’s teeth, which is used to generate a virtual 3D model of their mouth. This model serves as the blueprint for the fabrication of the aligners, allowing for precise customization and alignment. The orthodontist, use this 3D model to plan all the steps of your treatment. Here we find one of the most important steps of your treatment. And regarding the Invisalign aligners, Align Technology stands as a pioneer, being the world’s largest user of state-of-the-art 3D printing technology.

Each aligner is meticulously crafted using bio-compatible polyurethane resin, ensuring both safety and durability. What sets Invisalign apart is its ability to produce aligners that are not only effective but also highly individualised. Unlike traditional braces, which follow a standardised treatment protocol, Invisalign aligners are tailored to address the specific needs and progress of each patient.

The beauty of 3D printing lies in its versatility and efficiency. With traditional manufacturing methods, producing custom orthodontic appliances can be time-consuming and labour-intensive. However, with 3D printing, the entire process is streamlined, allowing for faster turnaround times and greater flexibility in design.

Moreover, the use of 3D printing technology enables continuous innovation and refinement in orthodontic treatments. As researchers and engineers continue to explore new materials and techniques, the possibilities for enhancing the patient experience are virtually limitless. From improved comfort to accelerated treatment times, the future of orthodontics is undoubtedly shaped by advancements in 3D printing.

In addition to its technological prowess, Invisalign has earned the trust of patients and professionals alike through its commitment to quality and safety. With FDA approval dating back to 1998, Invisalign has established itself as a leading authority in the field of clear aligner therapy. Patients can feel confident knowing that they are investing in a treatment that is not only effective but also backed by years of research and development.

In conclusion, orthodontic treatments with aligners represent the future of orthodontics, offering a modern and patient-centric approach to achieving straighter smiles. With the integration of 3D printing technology, companies like Invisalign are leading the charge towards a more personalised, efficient, and accessible orthodontic experience. As the field continues to evolve, one thing is clear: the future of orthodontics is indeed a 3D one.